Contaminants of hydraulic oil are broadly defined as any substance that impairs the proper functioning of the fluid. Air fits this definition and therefore when air becomes entrained in the oil, corrective action is required to prevent damage to both the oil and the other components in the hydraulic system.

Air can be present in four forms:

- Free air - such as a pocket of air trapped in part of a system.

- Dissolved air - hydraulic oil contains between 6 and 12 percent by volume of dissolved air.

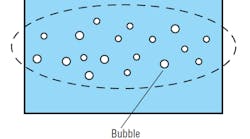

- Entrained air - air bubbles typically less than 1 mm in diameter dispersed in the oil.

- Foam - air bubbles typically greater than 1 mm in diameter that congregate on the surface of the oil.

Of these four forms, entrained air is the most problematic. Pre-filling components and proper bleeding of the hydraulic system during start-up will usually eliminate free air. Small amounts of foam are cosmetic and generally do not pose a problem. However, if large volumes of foam are present, sufficient to cause the reservoir to overflow for example, this can be a symptom of a more serious air contamination and/or oil degradation problem.

Why is entrained air bad?

Negative effects of entrained air include:

- Reduced bulk modulus, resulting in spongy operation and poor control system response.

- Increased heat-load.

- Reduced thermal conductivity.

- Fluid deterioration through increased oxidation and thermal degradation (dieseling).

- Reduced fluid viscosity, which leaves critical surfaces vulnerable to wear.

- Cavitation erosion.

- Increased noise levels.

- Decreased efficiency.

Gaseous cavitation

As pointed out above, hydraulic oil can contain up to 12 percent dissolved air by volume. Certain conditions can cause this dissolved air to come out of solution, resulting in entrained air. When hydraulic oil temperature increases or static pressure decreases, air solubility is reduced and bubbles can form within the fluid. This release of dissolved air is known as gaseous cavitation. Decrease in static pressure and subsequent release of dissolved air can occur at the pump inlet, as a result of:

- Clogged inlet filters or suction strainers.

- Turbulence caused by intake-line isolation valves.

- Poorly designed inlet (diameter too small, length excessive, multiple bends).

- Collapsed or otherwise restricted intake line.

- Excessive lift (vertical distance between pump intake and minimum fluid level).

- Clogged or undersized reservoir breather.

Other causes of decreased static pressure include changes in fluid velocity through conductors and orifices, flow transients and faulty or incorrectly adjusted anti-cavitation or load control valves.

External ingestion

Air entrainment can also occur through external ingestion. Like gaseous cavitation, this commonly occurs at the pump as a result of:

- Loose intake-line clamps or fittings.

- Porous intake lines.

- Low reservoir oil level.

- Faulty pump shaft seal.

Other causes of air ingestion include faulty or incorrectly adjusted load control valves, which can result in air being drawn past the gland of double-acting cylinders, and return oil plunging into the reservoir (drop-pipes extending below minimum oil level should be fitted to all return penetrations).

Prevention is better than cure

Like all other hydraulic problems, proper equipment maintenance will prevent the occurrence of most air contamination issues. However, if the oil does become contaminated with air, not identifying the root cause and fixing it can be costly mistake. And to discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get "Six Costly Mistakes Most Hydraulics Users Make... And How You Can Avoid Them!" available for FREE download here.