Compact hydraulic hose is shown undergoing pressure and flexibility testing. The hose exceeds twice the ISO 18752 requirement for one million pressure impulses at 1â

the hoseâs maximum working pressure.

For decades, SAE J517 has published guidelines for 100R1 through 100R12 series hydraulic hoses. These manufacturer-driven SAE standards have been based on design, construction, and pressure ratings to ensure that hydraulic hoses meet minimum construction requirements. They established minimum pressure ratings for various hose IDs (inside diameters) and were later revised to also include constant-pressure hoses—such as R13, R15, R17, and R19, where pressure rating remains constant within a group regardless of size.

More recently, however, hydraulic system designers began adopting ISO specifications. Many large OEMs switched to ISO standards in their design and manufacturing processes to ensure the sale and service of their equipment globally. Released in 2006, ISO Standard 18752 for hydraulic hose is relatively new to North American manufacturers.

ISO Standard 18752 takes a different approach, reflecting the design practices of users who typically design hydraulic systems based on performance and pressure requirements. Hydraulic hoses are classified in ISO 18752 according to their resistance to impulse pressure in four Grades: A, B, C, and D. Each Grade is then classified by the outside diameter (OD) of the hose into Standard Types (AS, BS, CS) or Compact Types (AC, BC, CC, DC).

Each grade level requires a specific number of impulse cycles the hose must meet at a specified temperature and impulse pressure. Parker’s new 787TC and 797TC series hoses—rated 35.0 MPa (5,000 psi) and 42.0 MPa (6,000 psi) constant pressure, respectively—not only meet the minimum 1 million cycles required in Grade D, Type DC, but have been successfully tested to 2 million impulse cycles at bend radii smaller than those required by ISO 18752.

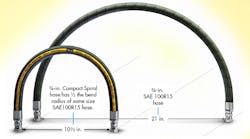

Same ID, Smaller OD

The inside diameter of the 787TC and 797TC hoses is the same as common SAE spiral hoses. However, its OD is smaller, which makes the compact hose easier to fit into tight spaces and—perhaps more importantly—lets you bend it to a smaller bend radius with no decrease in pressure rating or life, and with less required bending force.

Key to the design success of the Compact Spiral hose is a proprietary Nitrile-based inner tube compound that is both stronger and thinner than what has been traditionally used in standard spiral hose. The overall strength properties of the new inner tube compound are such that it is possible to have the same ID, yet reduce the overall OD and size without sacrificing the pressure and sealing capabilities. In addition, the reduced tube wall thickness provided the opportunity to proportionally redesign the wire reinforcement, which led to an additional reduction in the hose OD.