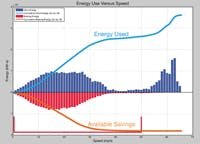

During a typical collection route, the blue represents the amount of energy (fuel) used to proper the vehicle. The red represents energy lost in the form of heat at the friction brakes. Parker’s Advanced Series Hybrid Drive captures the majority of this braking energy in accumulators and uses it to accelerate the vehicle, reducing engine and fuel demand.Parker’s stage gate product development process integrates computer modeling, dynamometer testing, lab testing, and full vehicle on-road operation to validate performance per user criteria, such as functionality, quality, reliability and added value.

Although most testing is done at Parker’s engineering offices and labs, Parker is also evaluating prototype vehicles through a variety of acceptance tests that replicate real-world operation. A state-of-the-art vehicle proving ground contains all road and driver conditions required to validate vehicle drive performance and durability. Trucks are operated 24/7 in a controlled environment with professional drivers, mechanics, and fleet managers evaluating fuel economy, acceleration, braking, responsiveness, road loads, vibration, gradability, and other conditions that are encountered in refuse collection service.

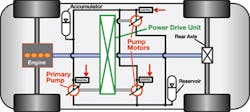

In addition to hybrid drive systems for refuse collection vehicles, Parker is developing variations of the hybrid drive for other on- and off-highway applications with high startstop duty cycles that require significantly different torque and packaging solutions.

For information, contact Vance Zanardelli, Energy Recovery Business Unit Manager, at (662) 890-5267 or email [email protected]. Visit www.hydraulicspneumatics.com to see additional images, including engineered drawings of the PDU and drive shaft.