Updated hydraulic presses save O-ring maker money, time

Updated hydraulic presses save O-ring maker money, time Appeared in print as "New tricks for an old press"

The Trelleborg Sealing Solutions facility in Northborough, Mass., has used its presses to mold O-rings for the past 20 years. Company officials decided to expand operations by molding more complex rubber parts using these same presses.

They evaluated their presses to decide what could be done to make the transition from molding O-rings to producing more complex molded rubber parts. After a thorough inspection, it was determined all of them could be retrofitted if the controls were upgraded. The upgrade required the addition of closed-loop velocity/position and pressure (tonnage) control.

A user-defined bump function had to be incorporated into the press cycle to enable the presses to perform in the following sequence:

• The press must close rapidly until a pre-defined target position is achieved.

• A customer-defined reduced velocity profile takes command until the mold has closed.

• The press automatically shifts to tonnage control. The user-defined tonnage profile and the defined bump function - controlled via closed-loop pressure and position control - work together while the part forms.

• PLCs controls a user-defined timing function.

Upgrading the hydraulics

Trelleborg called on Greenerd Hydraulics, a division of Greenerd Press & Machine Co., Nashua, N. H., to perform the upgrade. The first step in upgrading Trelleborg's presses required converting the existing hydraulic system pump controls to provide closed-loop pressure control via a 0- to 10-V signal. Consequently, proportional pressure control was added for adjusting the system tonnage. However, the existing proportional directional controls on the presses were found adequate to manage velocity and position, so they were not upgraded.

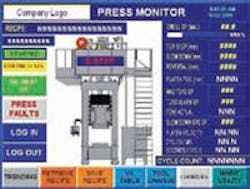

The presses were also outfitted with new Allen- Bradley programmable logic controls (PLC) to handle both closed-loop velocity and tonnage control with predefined velocity-to-tonnage control switch over point. Programmable touchscreens were also provided as an easy-to-use operator interface to simplify and reduce press setup, fine-tuning, and changeover times.

“Greenerd Hydraulics did a great job upgrading our existing presses,” commented Barrett Senecal, lead engineer and manager of physical plant services for Trelleborg’s Northborough facility. “The services were provided right at our facility, so we didn’t have to ship out any machines. We are now manufacturing more complex molded parts on the machines previously used just for O-rings. Tech support after the installation has been extremely responsive as well.”

In addition to supplying all the components for the upgrade, Greenerd Hydraulics provided on-site PLC and touchscreen programming, installation of all the new hydraulic components, and assistance with rewiring the machines. The presses were upgraded in just one week, programmed and ready to run. Greenerd then provided training for both the set-up technicians and machine operators to ensure a smooth transition.

Upgrading pays off

Trelleborg was able to expand its business with a conservative investment for the injection molding machine upgrade to enable machines to be capable of producing more complex parts. “When compared to purchasing new machines, having the Greenerd Hydraulics upgrade on our existing presses saved us almost $200,000,” noted Senecal. “The upgraded presses were not only costeffective, but also reduced cycle times by 42%.”

This information was submitted by Tim Dining, of Greenerd Press & Machine Co. Inc. For more information, visit www. greenerd.com. For information about capabilities of Trelleborg Sealing Solutions, visit www.tss.trelleborg.com.