Converting from Hydraulic to Electric Actuators: Key Steps to Follow

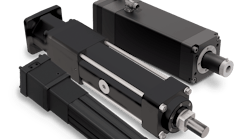

Use of electromechanical systems is increasing in several industrial machinery applications because of the precision and reliability provided. In many cases, they are replacing the hydraulics traditionally used in these machines.

While hydraulics will continue to be the technology of choice in many applications, for those where an electromechanical (i.e., electric actuator) option can be used it is important to understand how to convert from one technology to the other to ensure optimal machine performance.

Ryan Klemetson, Business Development Manager at Tolomatic, explained during a webinar hosted by the company on converting from hydraulic to electric actuators, that key steps to a successful conversion include determining the loads and forces of the application, and defining its required motion profile and cycle rate.

Following these steps will ensure the performance of an industrial machine is maintained and the benefits of converting from hydraulic to electric are achieved.

Factors to Consider Before Converting to Electric

When looking to replace a hydraulic system with an electromechanical one, it is important to take some factors into consideration to ensure the conversion is feasible.

One of the first factors to assess is the space envelope available for the system. As Klemetson explained in the webinar, hydraulics are very power dense and so machines have always been designed to optimize footprint. Because of this there may not be room for an electric actuator and its accessory components.

Electric actuators tend to require more space than a hydraulic cylinder because they are longer and wider. There is also mounting design work which needs to be taken into account.

Force levels and stroke length should also be considered, again in relation to how much space is available. While today’s electric actuators can achieve high forces they are not as power dense as hydraulics which means they need more space to provide forces similar to that of the hydraulic cylinder they are replacing.

“It is all about finding the right tool for the job,” said Klemetson. Therefore, having a good understanding of the machine design and its intended use will aid in determining if an electromechanical system will fit the application.

READ MORE: Increased Demand for Uptime and Reliability Driving Move to Electric Actuators

Accurate Force Measurements Ensure Proper Electric Actuator Sizing

Appropriately sizing the electric actuator that will be used in place of a hydraulic cylinder is one of the first steps in shifting from a hydraulic to electromechanical system. To do so, it is necessary to determine the force and load of the system.

Klemetson said Tolomatic always recommends measuring the force of a system as opposed to basing it on system pressure which is often done using the following formula:

Force = Area of the Cylinder x Rated System Pressure

This can result in an electric actuator solution which is oversized and overpriced. Instead, a more accurate measurement of force can be achieved by measuring hydraulic pressures in a cylinder while a machine is in operation.

“Where to measure is kind of a good, better, best,” said Klemetson. “The best place to always measure would be right at the point of work.” This is not always feasible though, but there are ways to still get accurate force measurements.

Using the good, better, best analogy, there are three areas within a hydraulic system where pressure measurements can be taken (see Figure 1 below):

- Good – Measure pressure at the valve, which is the commonly used option when converting to electric actuators. It is the furthest distance from the work point, though, increasing the potential for errors in actual versus measured pressure.

- Better – Measure pressure between the hydraulic system’s valve and cylinder. However, pressure-compensated flow controls and needle valves or other inline accessories could influence pressure.

- Best – Measure pressure at the hydraulic cylinder. This is the most accurate location for reading pressure at the point closest to where work is happening but may also be the least accessible location.

“The more accurate you are in measuring, the more optimized you’re going to be as far as the cost of your system,” said Klemetson.

Because every hydraulic system is different, Tolomatic recommends measuring both working pressure of the system and the return pressure as there is the possibility of high return pressure between the system’s cylinder and valve. This can reduce the total force of the system.

Therefore, it is recommended to place measuring gauges on both the extend and retract ports of the hydraulic cylinder (see Figure 2 below) and calculate effective surface pressure:

Force = (Area1(πr2) x P1) – (Area2 (πr2)x P2)

He gave the example of a small hydraulic system featuring a 1.5 in. bore cylinder with 0.75 in. rod and pressure relief valve set at 1,500 psi (103 bar). If doing a simple Area x Pressure calculation, the resulting force would be 2,60 lbf.

But if 250 psi (17 bar) of backpressure is factored in, that leads to a 40% reduction in required force (1,788 lbf) and thus a smaller sized system than might have originally been designed. Taking backpressure into account “could literally in some instances save you thousands of dollars,” said Klemetson. “So, we always recommend this as the most accurate” method of determining force requirements.

READ MORE: The Basics and Benefits of Electromechanical Actuators

Watch Tolomatic’s video “Sizing Electric Actuators for Hydraulic Replacement” to learn more about properly selecting the right actuator for use in place of a hydraulic cylinder.

Know Your Application for Component Selection

Understanding the desired motion profile of an application is another critical step when replacing a hydraulic cylinder with an electric actuator. It can be captured simply with a stopwatch or a camera to help determine the requirements of the application.

“It’s important to understand what is necessary – either I need to move at a given rate or I need to move a distance in a given time,” said Klemetson. “The reason this is important is typically when you get into larger force applications, servo motors don't spin as fast when they are very large. You may only have 2,000 [or] 2,500 rpm versus 6,000 rpm.”

By understanding whether it's time or speed that is important to your process and application, it is possible to reduce your motor speed by about 50% in some instances.

It can also help to inform component selection for the electromechanical system. Choosing the appropriate electric actuator screw technology (Acme, roller or ball), for instance, will correlate not only to system performance but also potential heat generation and maintenance requirements.

Klemetson noted during the webinar that roller screws tend to perform better than ball screws from a longevity standpoint in pressing and high-shock applications. Roller screws are known for their high force capabilities, low maintenance and high efficiency, all of which benefits these types of applications.

When you have a good understanding of your application and maintenance needs, it plays “into picking optimized components from a size and ultimately a cost perspective,” he said.

Take Full System Needs into Account

Klemetson said it is also important to remember you are engineering a system and therefore all necessary components need to be factored into the design process. Besides the electric actuator there is the motor and the drive which need to be taken into consideration as well as the power level that will be used.

“All of these play into the electrical side of it,” he said. Here again, understanding your application needs will aid with selecting the right types and sizes of electrical components that will be required.

One of the aspects which he said is often forgotten about is the cabling. “Hoses [and] fittings don’t care too much about laminar flow or turbulent flow but with electricity it’s pretty important,” said Klemetson. “Anybody that is going to be designing a system, make sure that proper cabling is selected, [and] proper wiring and installation cable dressing is followed.”

He said Tolomatic will often receive calls from customers that their actuator is not moving, and it turns out to be an issue with grounding, shielding or cabling. “From that standpoint, it can be a very challenging thing…and a chronic problem if it is not addressed at the beginning.”

Therefore, it is important to remember all components that will be used in an electromechanical system and that everything will work together as desired.

By following these steps, it is possible to achieve a successful conversion from hydraulic to electric actuation in your industrial machinery.