Electromechanical Cylinder Offers Varied Benefits in Range of Heavy Equipment Applications

RISE™ Robotics began developing its electromechanical alternative to hydraulics, the RISE™ Cylinder, in 2011. Since then, the company has advanced the technology and formed several industry partnerships to bring the RISE™ Cylinder to market.

“The RISE™ Cylinder is the most advanced yet familiar linear actuator technology,” said Arron Acosta, CEO, RISE™ Robotics in an interview with Power & Motion. This is because it provides similar performance to hydraulics in regards to its high force, high speed, long stroke, and push and pull motion.

“But it is the most advanced because it leverages advanced belt technology, with a novel way to apply that belt technology so that we can efficiently convert power from the motion of a motor into the push and pull motion in a rod,” he explained.

READ MORE: Comparing Electric and Fluid-Power Actuators

The RISE Difference

The RISE™ Cylinder is a direct mechanical transmission solution which is what enables it to perform in a more efficient manner than hydraulic alternatives. As there is no fluid utilized to create motion, there is also no heat generated or energy wasted which provides more efficient operation.

OEMs who are electrifying their vehicles and equipment are currently challenged with reducing battery size, extending run times, and ensuring durability in heavy-duty applications. With the efficiency provided by the RISE™ Cylinder, Acosta said manufacturers can achieve these goals. “In short, the benefit of the RISE™ Cylinder is smaller batteries and longer run times,” he said. “But unlike other electromechanical solutions, it is the most affordable and the longest lasting technology.”

The cylinder is durably designed and capable of providing high forces as well as long strokes in the range of 100,000 lbs. and 10 m, respectively, which benefits use in heavy-duty mobile applications such as forklifts and construction equipment.

Blake Sessions, Chief Technology Officer at RISE™ Robotics, said in an interview with Power & Motion the company aims to improve every possible aspect of how machines perform. In addition to integration of the RISE™ Cylinder, it also provides battery packs and other system components for electrification. Therefore, he said RISE™ Robotics is more than a cylinder company and instead sees itself as a power transmission company.

During a recent project with Anthony Liftgates, Sessions said RISE™ Robotics “developed everything from the battery terminals through to the motion; all the battery management systems, all of the system architecture, [and] all of the software. This reinforces the point that we’re not here to ship a cylinder and sub out one cylinder for another.”

Instead, RISE™ Robotics is aiming to be a full system supplier for electrification. This can be beneficial for many OEMs as they may not have the in-house capabilities to develop and integrate the necessary technologies to electrify their vehicles and equipment.

Reduced Energy Draw Increases Liftgate Battery Life

RISE™ Robotics announced its partnership with Anthony Liftgates in September 2021. It incorporated the RISE™ Cylinder and accompanying electrification technology into a liftgate from Anthony which was then exhibited at The Battery Show 2021—an annual trade show highlighting the latest in battery and other electric vehicle technologies.

Sessions said the partnership began a couple of years prior to that when Anthony Liftgates visited RISE™ Robotics at its facility in Somerville, MA. At the time, the RISE™ Cylinder was undergoing heavy-duty testing on a test stand. Anthony Liftgates liked what it was seeing from the cylinder during this testing and expressed interest in the technology.After the visit, Anthony Liftgates shipped one of its liftgates to the RISE™ Robotics team so they could attempt to integrate the cylinder and associated technology. “We were able to retrofit that machine with our cylinder technology and with our power systems, and really show from the beginning what the end game looks like,” said Sessions.

He explained that liftgates are typically accompanied by two box sections which are welded underneath the truck onto which the liftgate is attached. One box contains the batteries for the liftgate and the other the hydraulic components for lifting the gate such as the motor, pump and reservoir valves.

By integrating its electromechanical cylinder into the liftgate, RISE™ Robotics was able to eliminate the hydraulic components and the box which contained them. This reduced system complexity as well as vehicle weight.

Ease of installation was another benefit Sessions noted. “You can install cylinders in a matter of minutes instead of days because it is orders of magnitude faster to bolt and plug in components than it is to set up hydraulic circuits,” he explained.

Once RISE™ Robotics demonstrated what was possible with the integration of its technology, it began a more hand-in-hand collaboration with Anthony Liftgates to improve upon their design across the board said Sessions. This included the removal of a cylinder while maintaining the functionality of the liftgate.

By integrating the RISE™ Cylinder, he said the battery problems—keeping them charged and ready to provide power as needed—which often occur in liftgate applications are eliminated. Other solutions in the industry include use of solar panels to provide extra power or even fans under the truck acting as generators. But the RISE™ Cylinder solves “the root of the power consumption problem,” said Sessions by operating more efficiently and having a lower power draw.

Beyond that, he noted the electromechanical solution is able to provide safe and smooth movements unlike hydraulics which can sometimes be jerky. As there is no fluid used in the cylinder, its environmental impact is minimal as there is no need to worry about possible contamination caused by oil leaking out of the system. In addition, Sessions said there are not as many materials used for the cylinder which brings additional weight savings to the application.

The final major benefit he said of the RISE™ Cylinder is the quality of telemetry which can be integrated into the liftgate. Integration of telemetry is becoming more common in the industry to better evaluate how components are operating. RISE™ Robotics’ technology is a completely solid-state design said Sessions with sensors on everything to enable continuous monitoring of voltage, speed, position and other parameters. This helps to ensure the system is operating correctly at all times and immediately alert the truck owner if an issue is detected.

Improved Precision and Military Vehicle Weight

In recent months, RISE™ Robotics has announced several projects it is working on with the U.S. Air Force (USAF). Through these, its electromechanical cylinder will be integrated into various machines to help modernize their designs by making them more productive.

Acosta said that while RISE™ Robotics’ technology can benefit electrification and efficiency, the precise control and other features of the RISE™ Cylinder can help to provide faster operations and reduce maintenance which are all beneficial for the military.

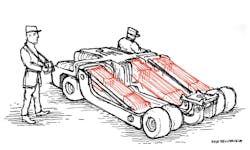

One of RISE™ Robotics’ projects with the USAF is to develop a prototype of a munitions handling unit for global strike command. The goal is to enable faster loading and reduce downtime.

“[USAF] had identified a problem long before RISE™ came along, where these munitions handling units’ load times are longer than they should be because the hydraulics are unable to precisely control the motion,” explained Acosta. “Their hydraulics are only doing an eighth of an inch precision, so operators are constantly overshooting and undershooting.”

There is a lot of repositioning operators need to do, which prohibits their productivity. Issues with sag and drift often occur as well due to the eventual wear of the hydraulic components noted Acosta. This can cause uncommanded motions to occur, requiring operators to continually reposition the unit.

Integrating the RISE™ Cylinder into the munitions handling unit will enable operators to get quickly and precisely to a position and stay there, said Acosta. “That is our one of our major initiatives, to demonstrate the value of the fastest, most precise actuation technology [the RISE™ Cylinder].”

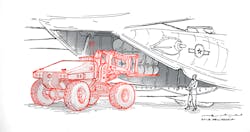

RISE™ Robotics is also working with the Air Force Research Lab on the development of an ultralight forklift. For this project, Acosta said the company will develop a dual-purpose forklift which is actually more akin to an articulated wheel loader utilized on a construction site.

The USAF uses this machine to load and unload cargo from planes; it is transported to various locations on these planes as well. Creation of a lighter weight machine will make it easier to transport and reduce the amount of load carried on planes.

RISE™ Robotics will integrate its electromechanical cylinder and associated technology to help reduce the weight of the forklift. Doing so eliminates the need for a pump box and other hydraulics components which can be heavy and add pounds to machinery. It also allows a reconfiguration of some of the physical framing and component infrastructure which has the potential to enable further weight reductions or other design benefits. “We are going to be doing work on figuring out, ‘what does the loader of the future look like?’ And we are really focusing on making ultra-light loaders,” said Acosta.

One of the challenges to be figured out is how light the machine can be made as it will still need to be able to lift heavy loads. “There is only so light you can go because you need counterbalance,” he said. “So we are going to take it down [a few pounds] and really see how far we can go.”

Technology Scale Up for Heavy Machinery Electrification

In May 2022, RISE™ Robotics announced it would begin collaborating with Danfoss Power Solutions on electrification of off-highway equipment using the RISE™ Cylinder. “Danfoss is thrilled to collaborate with us to explore what we have achieved and how it can benefit them and their customers,” said Acosta.

For RISE™ Robotics, the partnership with Danfoss provides the ability to scale its technology and bring it to various machines and regions around the world. While it could slowly work at building up its manufacturing capacity, Acosta said that can be time consuming and capital intensive. “At the end of the day, when we succeed that means the existing industry would shrink,” he said. “And that just seems like a slow and destructive technique.“The new partnership with Danfoss is an example of how we are both innovative and both working to find ways to meet the demand for electrification from customers,” he continued.

Working together will actually help accelerate development of necessary technologies and the creation of near-term low-carbon solutions, said Acosta. This is because both companies will be able to bring together their expertise and industry knowledge which makes it easier to ensure the right technologies are developed for given applications.

Acosta said RISE™ Robotics will bring to the partnership its engineering services and the IP for its technology, and will work together with Danfoss’ innovation team which has experience in a variety of technologies and applications that it will bring to the partnership.

Much of the work being done between the two companies is still in the early stages, but in general Acosta said there is a broad vision to bring electrification to a range of heavy-duty equipment. For the time being, the companies are focusing on one specific example and will expand its efforts from there.

“When we succeed with that example, because of its size, performance and demanding attributes, it will become a case study or a bookend on multiple parts of the business,” said Acosta. Essentially, between the Anthony Liftgates partnership and Danfoss collaboration the industry will be able to see the broad range of applications in which the RISE™ Cylinder can be applied. “Other customers will be able to see if they can interpolate [possible uses] between those [applications]. They will be able to see the beginnings of a full catalog [of solutions],” he concluded.