Compressed air may be more efficient than you think

People no longer think of industry or technology without compressed air. Some examples of compressed air technology are the filling of widespread PET bottles, and the purification of water in sewage treatment facilities.

The economic and energy efficiency factors of compressed air as a working fluid are common topics of criticism. Compressed air technology expert Prof. A.P. Weiss, of the Amberg-Weiden University of Applied Sciences says, “In the past, it was the efficacy which came foremost…not the expenditure/benefit ratio.”

Climate protection and energy conversion have called for people to reverse their thinking and focus on efficiency.

Economic and scientific fields have for a long time pursued new examples whereby proven technology goes hand in hand with innovation. The common aims are clearly outlined: continuous improvement of the energy efficiency of compressed air, and to make compressed air technology sustainable.

Weiss is convinced, “When one makes use of the full potential, compressed air in operations is indeed a form of rational energy usage for the future”

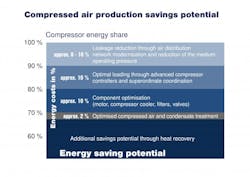

A study conducted by the European Union shows that 18% of electrical energy in industry is consumed in generating air pressure as a service fluid. According to this study, a third of this electricity can be saved with the application of appropriate technology and more efficient systems.

With a need for competent skilled technicians in the pneumatics industry the curriculum at the HAW Amberg-Weiden institute has included compressed air technology and research courses since 2000. The university has worked closely with the industrial sector for optimal training.

Industrial use

In the mechanical engineering department, Deprag Schulz GMBH & Co. became a congenial partner in developing innovative air machines/tools. For example, the development of fast-running turbines for compressed air, CO2, natural gas, steam and other vapors, and the conception of generators necessary for the same would lead to Deprag’s green energy turbine system- a technology with which small residual quantities of process gases can be profitably converted to electricity.

Compared to electrical motors, compressed air motors and compressed air-operated tools distinguish themselves for their high output in terms of short-term-sudden release of power (impact tools), speed (cylinders), overload and usability under duress, high duty cycles, robustness and relative immunity to humidity and dirt.

Additionally, there is the explosion-proof protection of compressed air motors. In an explosion-risk environment, where a single spark can pose a significant threat, electronic tools can be used only under specific circumstances, but there are no such pre-requisites with compressed air equipment. The design of a compressed air motor and its normal operation involve no risk of overheating, and no electrical connections.

Compressed air optimization

Critics fault the economic factor of compressed air technology. They claim that depending on the type, a compressed air motor does not optimize the expansion process of compressed air. As a result, more compressed air is consumed than is absolutely necessary. They argue that this means the consumption of energy for electrical compressors is higher than when the same amount of power is used directly for an electrical tool.

The Deprag compressed air motors project manager, Dagmar Dübbelde counters, “Compressed air motors and electrical motors cannot be compared one on one. The application is determined by the drive solution.”

“In a packing machine, a motor should produce 450 rpm with no load. An application with a load torque of 25 N-m is induced at a reduced speed for an extended period of time at the end of the packaging line. Electrical motors cannot be overloaded over extended periods. This would lead to overheating of the motor. Thus, an electric motor for said packaging machine is planned for the load torque, and would require an output of 1170 W (25 mm × 450 rpm ÷ 9550),” says Dübbelde.

The calculation with a compressed air motor is completely different. Dübbeldesays, “Both demands of the packaging machine can be accomplished with the favorable torque of compressed air motors, using a smaller motor. For this application we would select a compressed air motor with a nominal torque of 15 N-m and a nominal speed of 275 rpm. Given that the working torque is less than the nominal torque, the motor runs at close to the no load torque, with 450 rpm, under low demand.”

Compressed air motors are most effective when they operate close to their nominal revolution speed. With this, Dübbeldeadvises all users, “The pneumatic motors must be carefully designed for their use in a way that saves energy and running costs.” Simple conventional measures alone are enough to increase economic viability, “The internal pipe diameters recommended by the manufacturer must absolutely be observed at all times. Every bottleneck works as a throttle and reduces the output of the pneumatic motor.”

Reducing energy consumption

Manufacturers of the compressors also make their contribution to reduce the energy consumption of compressed air generation comprehensively by 30%.

Kaeser Compressors Inc. offers users a PC-supported compressed air audit, which determines accurately the actual air requirement for new systems and also for existing installations.

Erwin Ruppelt from Kaeser Compressors says, “The more transparency a compressed air system offers over cost saving potential, the closer all those involved come to throttling the energy consumption related to the generation of compressed air by a potential one third advantage in terms of company results and the environment.”

Through the audit all savings potential is exposed and the compressed air installation can be configured for maximum reliability, energy efficiency, and also optimized for future requirements. Modern compressor controls that communicate with industry PCs, allow for precise data collection and evaluation, and form the basis of a complex system management that can reduce energy consumption significantly. This includes existing installations.

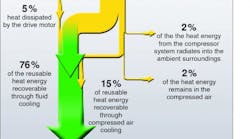

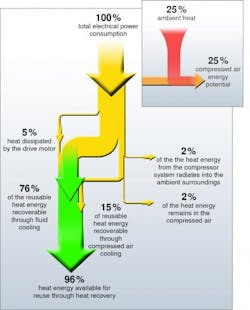

Compressed air technology is capable of even more. Erwin Ruppelt says, “In the domain of heat recovery, more valuable heat energy can be saved. A 100% of the drive energy supplied to a compressor is converted into heat. Up to 96% of this energy can be used a second time, either for heat purposes or as process heat.” He says that specific use of compressor waste heat allows for a reduction in consumed electrical energy, but also the heat energy requirements of a company.

Potential savings

Possible efficiency increase with specific heat recovery profiles using screw type compressors is shown by example of a mill operation. Comparing the year 2007—when compressor waste was still not being used — and 2011 says a lot. Due to gas heating, a total of 552,000 kW-hr was saved by this company. The savings is equal to 36% of total heating costs for the company. The following annual average was possible: the use of 52% of the compressor output for heating purposes a second time, the top measurement value was 71%.

Innovative developments in compressed air technology promise a reduction in energy costs. For example, pneumatic turbine motors, applied here instead of the traditional vane motor, makes use of the expansion process of the compressed air. Thus, the energy medium is used far more efficiently, and the machine’s air requirements are reduced by one third.

The turbine motor picks up additional points with its unsurpassed output (kilogram/kilowatt) — in terms of power to size ratio it is half the size of a vane motor.

Dubbelde says, “By exchanging a vane motor the size of a fist for turbine motor of equal size, I can double motor output on the spot.”

The turbine requires no lubrication, and there are no wear parts, this only increases the economic viability of a turbine.

Prof. Weiss states, “Today, compressed air is more efficient that ever before, but if the factor of heat recovery is not considered, a company will see no economical advantage.”

In the future he predicts, “Compressed air systems could be used more and more in the decentralized monitoring of excess renewable energy. With the available Kaeser compressors and the innovative GET turbine generator of Deprag, this CAES (Compressed Air Energy Storage) short-term conservation of wind and solar energy — even if the kW rating is small — could be a prelude to a new field in application of compressed air technology.”