The oil which runs through a hydraulic system plays an important role in its performance, as well as that of the machine into which the system is integrated. Monitoring the condition of the oil is necessary to ensure it continues performing as desired.

Typically, this oil condition monitoring has been done through regular oil sampling which can be time consuming. However, there is increasing use of sensors to monitor the condition of hydraulic oil. This enables more continuous monitoring and improved maintenance practices because more immediate action can be taken upon detection of any anomalies.

In 2022, Hydraforce Inc. announced it would partner with Tan Delta Systems and Elevāt, a provider of IoT (Internet of Things) connected machine applications, to enable real-time oil condition monitoring in hydraulic systems.

Through this collaboration, Tan Delta’s oil conditioning sensor is integrated into manifold assemblies using HydraForce cartridge valves. With the sensor, “you have a component that can monitor continuously the condition of the oil which is really the bloodstream of vital functions on a piece of mobile equipment,” said Russ Schneidewind, Director of Business Development for HydraForce, Inc., part of the Compact Hydraulics business unit of Bosch Rexroth, during the Power & Motion webinar “Achieve Better Hydraulic System Maintenance with Oil Condition Monitoring.”

Elevāt's telematics solution enables hydraulic system information to be collected, analyzed and sent to machine owners or maintenance personnel so they can immediately perform maintenance if necessary, leading them to be more proactive than reactive when an issue is detected.

By bringing together their technologies and expertise, these companies aim to increase the use of oil condition monitoring to improve the maintenance of hydraulic systems.

Oil Condition Monitoring Sensors Provide Valuable Data

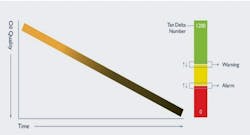

According to Chris Greenwood, CEO and co-founder of Tan Delta Systems, the company’s goal is to provide intelligent monitoring and maintenance with its oil conditioning sensor. “It’s all about getting the data that people need now in order to be able to manage [their] machines effectively,” he said during the Power & Motion webinar.

To do so, he said the Tan Delta technology looks at oil holistically – looking at every single aspect instead of focusing on one or two parameters such as particle count, relative humidity or viscosity as some other technologies do. While important factors, he said monitoring all aspects of oil condition is necessary to ensure no issues are missed.

“When you've got a machine that's running remotely, and you're relying on that data coming from the sensor, you don't want to…be in a position where it failed, but the sensor didn't see it,” said Greenwood. “A key thing for us is having that accuracy, repeatability [and] sensitivity so we know whatever's going on, we're going to be able to see it and then give that back to the customer in the form of actionable data.”

He noted that giving data is good, but if it is not meaningful, then it does not provide any value.

Some oil condition monitoring tools and techniques in the market have been lifted from the industrial sector which Greenwood said do not necessarily fit with the needs of the mobile equipment market. For instance, he said particle counting has always been a popular method of looking at hydraulic fluids but does not actually tell you anything about the fluid itself.

“It's only telling you if you've got material in the fluid,” he explained. “From our perspective, if you've got material in the fluid, then you've already got an issue. So, it's now just mitigating the issue rather than preventing it in the first place.”

Schneidewind said HydraForce’s hydraulic systems are critical to machine operation as they are typically used as the bridge between the electronic controller and the control of all the machine functions. Therefore, it is vital to ensure the quality of the oil running through these systems.

When the company has received complaints about a product not operating as it should, he said it is amazing how many times it has been because of the condition of the oil. “Contamination is a huge problem for us because our valves are made with very precise manufacturing and loads, and small tolerances,” he said. “Sometimes when we're trying to precisely control something, we have a very small opening in the valve that we're trying to control very accurately; changes in the oil affect all of that.”

HydraForce application engineers will work with a customer to determine the ideal situation for setting up the hydraulic system, but once it is in the field the company can no longer monitor it. And customers may not understand why the system is not performing as it should or what to do about it. However, integrating the Tan Delta sensor into the hydraulic system helps overcome this challenge by providing monitoring and information on what may be causing performance issues so they can be addressed.

Schneidewind said the design of the oil conditioning sensor is well suited for cartridge valve and manifold technology because it looks like a cartridge valve and threads directly into a port in HydraForce’s tank line. In addition, he noted the fluid flow past the sensor is beneficial. Both aspects enable the company to create a well packaged solution for its customers.

IoT Connects Systems to Improve Data Collection and Sharing

HydraForce had been working to build up its remote access capabilities for some time, said Schneidewind, when it formed the partnership with Tan Delta and Elevāt. While the Tan Delta sensor monitors the state of hydraulic oil, the Elevāt telematics platform allows that information to be collected, stored, analyzed and sent to all interested parties.

Adam Livesay, co-founder and CCO of Elevāt, said during the webinar that when the company works with OEMs or integrators, the goal is to connect the whole machine, everything from the hydraulics to the transmission to the engine and more. Sensors of various types play an important part in enabling this.

He said with intelligent solutions like Tan Delta’s oil conditioning sensor, information being collected by the sensor can be shared with Tan Delta for their input which can then be provided back to Elevāt and dispersed to the OEM who can inform its customer of any possible actions to take based on the analysis provided by Tan Delta. Sharing industry expertise in this manner enables better performance insights and maintenance solutions to be achieved.

It also takes the development burden off of the OEM; instead, those who have expertise in hydraulic systems, oil condition monitoring and connectivity can work together to provide a monitoring solution that brings together their industry knowledge to ensure all aspects will perform as desired.

“We're looking at all the machine data, and we're going to be sharing it with the experts that have built these components to tell us what the health is,” said Livesay. “That to us is the ultimate because we become almost like a Cisco router in essence [by collecting and sharing] the data.”

Sharing all of this information between the various industry experts creates a connected ecosystem to provide the most valuable solution to the market, he said. “This is the pinnacle. This is exactly what we want with IoT moving forward, is understanding what puzzle piece we are and how do we complement each other to provide the best value for the OEM and ultimately its end user.”

Interest in Monitoring Hydraulic Oil is Steadily Rising

Use of hydraulic oil condition monitoring technologies within the mobile equipment industry is growing. Schneidewind said interest in this type of solution is still in the early stages, but the biggest gains are being made with high value machines such as mining equipment.

In mining, unplanned downtime can be extremely costly due to the value of the material being collected and the expense of operating mining equipment. Accessing the machines can be difficult as well because of the remote locations in which they typically work. “If you can imagine having to do regular oil sampling and sending it out to be evaluated and shipped back, by the time you get the analysis the machine could already be having some problems,” said Schneidewind. “[The machine] could just go down in the middle of the work it has been doing and that would be an extreme cost to the mine.”

However, if an oil condition monitoring system is used it would be easier to detect issues much sooner and have alerts sent to the interested parties, minimizing unplanned downtime.

Schneidewind said there is a transition taking place in which OEMs and their customers are starting to see the value and potential cost savings associated with using these types of systems. This will help increase their industry adoption in the coming years.

Greenwood agrees there is growing interest in hydraulic oil condition monitoring. In addition to ensuring the performance of critical pieces of equipment, there is also a greater focus being placed on ESG (environmental, social and corporate governance). Monitoring systems can help to determine when maintenance is actually needed – instead of doing so on a schedule which could reduce unnecessary waste. And by helping mitigate possible issues as soon as they occur, larger problems or damage to environments and people can be minimized.

READ MORE - The Future of Oil Analysis: Converting to Electric Power and Sensors

He also noted the implications of reduced industry knowledge and service technicians, a challenge facing many market sectors. Sensors and other components enabling oil condition monitoring can help by providing the information on the possible issue at hand as well as what steps are needed to fix it – allowing those with any level of expertise to identify and address the problem so machines can get back up and running.

Elevāt’s Livesay sees use of oil condition monitoring technologies expanding beyond higher value machines as more companies deploy digital strategies. He said a massive shift has taken place over the last few years in which OEMs are now looking at internal IoT use cases particularly for maintenance and warranty claims.

“The Tan Delta oil conditioning sensor is a perfect device that gives them a lot more information and data they don’t currently have,” he explained. “In the past, OEMs might not have had to think about how they monitor [hydraulic oil] in real time because they didn’t have a connected machine.”

But now that machines are more connected, it is necessary to provide this information – to service tools, production lines and engineering teams. Livesay said it makes sense that if you are going to have a more connected machine then you are going to want to gather the most valuable information which is the condition of the hydraulic oil.

“As solutions like this [with Tan Delta and HydraForce] come out, and OEMs embrace smart sensing technology with better information, this is going to be a pretty big growth area over the next several years,” he concluded.