Automate 2023 Demonstrates Excitement, Need for Industry Education on Automation

This week I had the opportunity to attend Automate for the first time. Put on by A3 - Association for Advancing Automation, the event showcases all things automation for the industrial space — from motion control and other necessary components to robots, software, 3D printers and more.

The 2023 edition is expected to be the largest yet, with over 750 exhibitors over 300,000 sq. ft., 200 speakers and more than 25,000 registered to attend.

On the opening day of the event, A3 announced Automate will now be an annual event with the next iteration taking place May 6-9, 2024 in Chicago, IL, and again May 12-15, 2025 back in Detroit where the 2023 show is located. The association said in its press release it chose to move to an annual schedule due to overwhelming support from the back-to-back shows held in 2022 and 2023. And given the rate at which automation has grown in almost every aspect of life, it will help to provide further insights into the trends and technology necessary to keep this momentum going.

"Over the past several show cycles, Automate has grown substantially," said Jeff Burnstein, president of A3, in the association's press release announcing the new annual schedule for Automate. "What’s more, the pace of change in automation is staggering — attendees and exhibitors alike asked that we increase our frequency to an annual show to help keep them ahead of the curve."

This recognition of automation's growth was expressed by many of the people I spoke to at the event. Several companies noted the growth they've seen in recent years and the continued rise in automation expected in the coming years.

A key driver for this is the reshoring taking place in North America. The supply chain challenges experienced over the past 2 years has prompted many companies to look at bringing manufacturing back in closer proximity to customers. New facilities are being built in the U.S. as well as Canada and Mexico to aid with this and many are including more automation in these facilities to not only be more productive but also help alleviate the labor challenges facing the manufacturing industry.

READ MORE: Robots and Cobots Present Opportunity for Pneumatics

More Industry Knowledge is Required

While many conversations at Automate centered around the technologies enabling automation, and robots — so, so many robots of various types and sizes — a key topic which came up time and time again is the need to educate and simplify the transition to automation.

The need for further industry education, and the technologies and principles behind it — such as motion control — was evident from the education sessions which took place during Automate. Attendees had 10 topic tracks to choose from throughout the show which included keynotes, autonomous mobile robots, motion control certification and more.

As evidenced by myself and colleagues, conference and educational sessions were well attended, further demonstrating the desire for more information on automation and the technologies behind it.

Many manufacturers working in the area of automation are trying to do their part as well to help educate the industry on the subject and how to properly deploy it. This comes through their own educational efforts as well as providing more system solutions and engineering services to help customers add automation to their manufacturing facilities. Several companies noted during conversations at Automate they are focusing on simplification of their products for easy installation and programming, such as through development of software tools that are reminiscent of apps on a smart phone — all programming is built in and the user has to simply select the application(s) they want to install, allowing them to quickly get up and running.

During a discussion with Schneeberger, a developer of linear motion technology, the company said more and more customers are looking for solutions, not just components to ease their design process which it is working to provide. This was a sentiment expressed by many companies throughout the show.

Though not a new concept, offering full system solutions enables customers to receive all necessary components and software from a single supplier which helps to ensure they will all work together in a cohesive manner.

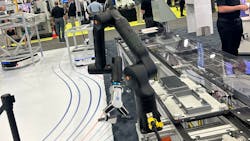

igus also demonstrated this industry need by exhibiting its Rebel robot arm and RBTX robotics marketplace, both of which are part of its low-cost automation portfolio. Through this program, igus is aiming to help lower the barrier of entry to implementation of robotics. Customers can order individual robotics parts, from any partner manufacturer or igus, or full robots and receive guidance on how to set up and deploy these automation solutions. As one member of the igus team noted during our discussion at Automate, a lot of people don't know where to start with automation. Easing the selection and installation process can help to overcome this.

As automation continues to grow, system solutions and industry education will become even more important to enable further uptake and growth.

We want to hear from you!

Were you at Automate this year? If so, what were your favorite things at the show? What struggles do you have with automation? How can the industry improve efforts to deploy automation solutions?

Let us know! Email me at [email protected] or reach out to us on social media.

Twitter: @TechnlgyEditor or @PowerMotionTech

LinkedIn: @PowerMotionTech

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech