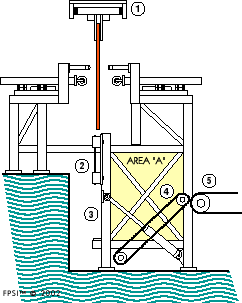

Figure B

5. Have lockout and de-energization drills to ensure that personnel know exactly how to make a machine safe to work on; some lockout situations are complex because someone might need to lock out numerous machines to make the situation safe. Refer to Figure B, which illustrates an actual machine. Routine maintenance and repair have to be carried out in area A. To lock the machine out safely, it is necessary to lockout mechanisms 1, 2, 3, 4, and 5 individually. Failure to do so could result in severe injury or death. It would be wise to have periodic lockout drills on these types of machines. Telling maintenance and service personnel how to conduct the service or repair in a classroom setting is one thing, doing it under the demanding pressures of a disabled production machine is another. When it comes to safe lockout, there is absolutely no room for error!

6. Make the "cracking" of connectors to remove stored energy a serious safety violation, and punish those who do it accordingly.

7. If a hydraulic machine is not designed to facilitate safe de-energization and verification, don't risk your life. Call the respective machine manufacturer for help. If you are told to crack a connector, refuse — it could kill you!

8. When purchasing or specifying hydraulic machinery or equipment, ask the supplier or manufacturer, if it complies with OSHA's standard for lockout with respect to safe de-energization and verification. If it does not, make the purchase of that machinery or equipment subject to compliance.

9. Contractors must obey your safety rules. In many cases, untrained service and repair personnel who are hired to work on your hydraulic machines do not follow good safety practices. In many cases, they have absolutely no training themselves. Ask about employee training and certification before hiring a contractor. Outside contractors are looked upon by your employees as experts. They are generally called upon to do either warranty work or because your personnel are not qualified to do the work themselves. If they are going to mentor your personnel, it is critical that they lead by example, especially when it comes to safety.

Conclusion

All hydraulic machines must be designed and built to comply with OSHA's standard for lockout with respect to safe and verifiable de-energization — otherwise, they are simply unsafe!

If, in the course of your work, you have to open a hydraulic system, and you find that you cannot safely de-energize the system or verify if the system is de-energized, never guess! Call the manufacturer and ask for guidance.

Oil escaping to atmosphere at high velocity can easily penetrate your skin. Skin penetration injuries have been recognized as devastating and can result in severe injury or death.

*This information was excerpted from this page on the Fluid Power safety Institute website.