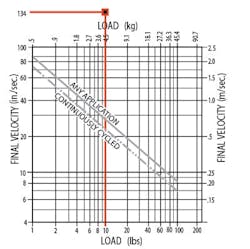

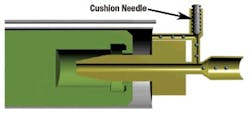

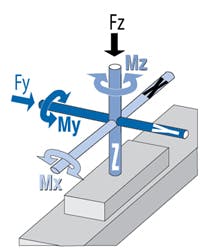

As shown in the graph, 134 in./sec is off the chart, and this rodless cylinder requires external shock absorbers to properly stop the load. Tolomatic recommends when a band cylinder needs external shock absorbers, remove the internal cushions and align the shock with the center of gravity of the load. Proper shock alignment eliminates additional moment loads which could damage the actuator’s bearing structures.

Once shocks were installed properly in this application, damage to the actuator was eliminated and the product performed flawlessly.

When designing with pneumatic actuators, don’t forget to factor in how fast the load really ends up moving (final velocity). And make sure to specify the right components – whether the actuator’s internal cushions or external shock absorbers – to stop the load within rated design parameters.

For additional information, contact Tolomatic Inc. at (800) 328-2174 or visit www.tolomatic.com

Tips for maximizing band cylinder life

Four factors affect the life of a band cylinder: load, speed, environment, and deceleration. The following tips will help you select the appropriate band cylinder for a specific application’s loads and speeds, as well as maximize cylinder life.