A formidable challenge to high-pressure seals is preventing extrusion, where high pressure tended to push the material through clearances of an assembly. Seals for the larger subsea coupler were designed to prevent extrusion.

The Stepseal 2A CR is TRELLEBORG’S new standard corner-reinforced rod and piston seals for single-acting use. Advantages include its anti-tilt design and its dimensions of the seal body, and the CR ring can be modified for easy installation. Safety issues were a constant concern throughout the seal development process to meet those frequently faced when working with heavy duty engagement of subsea equipment. Trelleborg officials and the STL team conducted a lengthy test program, including a full API Spec 6A temperature and pressure cycling program along with endurance cycle testing on the products in accordance with the ISO 10423 standard. STL also conducted two disconnects with 10,000 psi bore pressure, all completed with one set of seals.

The coupler provides new opportunities for remote emergency release system designs for subsea applications and also let people be removed from stab plate engagement functions on the surface. By being hydraulically retractable, it allows engagement of equipment both on surface and subsea to be separated from the comparatively delicate engagement of control system interfaces.

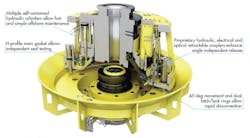

Because this is the first coupler of this size ever to be made with a hydraulically retractable element, STL is certain this will create opportunities for offshore beyond just its use in its XR Connector. The 2-in. hydraulically retractable subsea coupler was specifically designed for constant heavy-duty operations and works with very small fluid volumes to ensure rapid movement. It was also accommodates solids-laden fluids, such as drilling muds and well effluents. It is pressure balanced in both the extended and the retracted positions, ensuring the coupler will remain in position in the event of hydraulic control system failure. The assembly can also be tested to full system working pressure against the retracted coupler without the need for an additional test cap.

When retracted, the coupler stinger is flush with the coupler plate, preventing both dirt ingression and external impact on the retracted coupler from damaging the seals. The coupler is fully Lloyds design-verified and qualified to 3,000 m (10,000 ft) water depth, rated to 10,000-psi fluid pressure and up to 5,000-psi hydraulic function pressure. It can be used on subsea wellhead connectors, riser connectors, emergency disconnect packages, quick release stab plates, and emergency disconnect points.

STL has just completed the last round of testing and delivered the first coupler, and already it have received further orders. The benefits are clear that this cutting-edge product will enhance operations and service offerings, enabling customers to deliver the latest safety and operability enhancements to their clients.

Andrew Longdon is technical manager at Trelleborg Sealing Solutions.