Filter Elements in Hydraulic Filtration: The Key to Efficient Hydraulics

Whether in wind turbines, mining, agriculture or construction, the following applies everywhere: Hydraulic systems are essential for safe and efficient operation. Hydraulic fluid filtration is a proven solution for increasing the service life of these systems and reducing downtimes. But which filter element goes with which hydraulic fluid? Some key data can help to identify the correct answer, as well as the expertise of a filtration supplier with experience and extensive industry knowledge.

Wherever fluid technology has to ensure reliable, efficient performance and motion control, it depends on filtration. In eight out of 10 cases, problems with the hydraulics in compressors, excavators or mining machinery are related to insufficient or a lack of oil monitoring and maintenance.

As the power density of hydraulic systems and components increases, efficient filtration is becoming even more important. This affects both the functionality and the service life of the hydraulic components. To benefit from the properties of the fluids used for as long as possible, effective removal of impurities—both those that are produced and those that enter from outside—is crucial. This is because the aging process of hydraulic or lubricating oil fluids largely depends on the nature and amount of contamination present.

Eaton supports system designers with a broad and specialized range of filtration products that ensure a high degree of purity and reliable operation across all industries. Application-specific filter and accessory design plays a major role in the almost endless amount of media, process variables and ambient conditions: Eaton offers more than 4,000 different filter elements, each with matching filter housings. These filter elements are available with various filter materials, in different designs and filter ratings, to help protect important system components.The return-line, suction and pressure filter elements and elements for in-line filters are used in single and duplex filters for low-, medium- and high-pressure applications and are considered the industry standard in many places. In addition, there are mobile and stationary filtration systems, systems for contamination and condition monitoring, and auxiliary devices such as contamination indicators.

To find a suitable filtration solution with the right filter element, system and machine operators need to know which hydraulic fluids are being used. As a key element of the system, these fluids have to fulfill a wide range of tasks depending on the application, but this is precisely what increases the risk of declining performance due to aging.

The Oil Must Match the Application

Given the wide range of applications, the selection of hydraulic and lubricating oils on the market is similar to that of the available filtration products. The hydraulic fluids differ primarily in their base oils, such as mineral oil, vegetable oil, polyalphaolefins, carboxylic acid esters, polyalkylene glycols, phosphate acid esters and silicone oils.

This means that base oils can be divided into synthetic and native oils. Synthetic fluids are compounds produced by the chemical transformation of various starting materials such as carbon monoxide and hydrogen. Examples include polyglycol oils, polyalphaolefins and synthetic esters. Native fluids are obtained without chemical transformation through distilling and refining crude oil or various vegetable oils, meaning they have a natural base.

Base oils are mixed with additives in order to make them suitable as hydraulic fluids. In this way, the basic properties of the oils, such as viscosity, susceptibility to corrosion and resistance to oxidation can be influenced. In practice, a simplified nomenclature classifies hydraulic fluids according to their intended use and properties:

- Mineral oil base H (hydraulic fluids mostly used for stationary hydraulics).

- Fire-resistant HF (fire-resistant hydraulic fluids are used in various applications and industries such as mining, the steel industry or in aircraft engines, depending on their composition).

- Rapidly biodegradable HE (hydraulic environmental fluids are used in mobile hydraulics, for example in agriculture and forestry).

And the Filter Element Must Match the Oil

Given the variety of hydraulic and lubricating oils available on the market, it quickly becomes clear that selecting the right components (support tube, end caps, etc.) and filter materials (fiberglass media, stainless steel mesh, etc.) can be challenging—especially when using unusual or highly specialized oils. The materials used, including metals, alloys, plastics and sealants, must not only withstand the environmental conditions, but also be resistant to the oil used.

What is suitable for one oil can be damaged by another, which can lead to system damage and failure in the worst-case scenario. Common problems are leakage or contamination of the oil caused by dissolving or corroding material. In addition to the base oil, the additives used for the application are critical, as these can have significant impact on the behavior of the oil toward certain materials.

Another critical factor is temperature, as fluctuations of as little as 50°F (10°C) can significantly alter the chemical resistance of the materials used. Therefore, a resistance test is usually recommended, particularly for sensitive applications. In this test, the selected materials are immersed in the corresponding hydraulic fluid for a longer period of time, under conditions similar to those of the application. In this way, the resistance of the components to the oil can be realistically and practically tested. In a further step, oil that has already been used in the application is often also used in order to be able to check effects that are associated with oil aging.

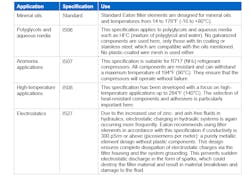

To simplify the accurate selection of a suitable filter element, Eaton has established a uniform internal specification (IS) for special filter elements in addition to the standard filter elements. The IS number indicates which filter element components are suitable for specific oils. Derived from the mineral oil used, the IS number provides users with direct and uncomplicated information about the filter elements that are suitable for the application.

This table provides an overview of the most important IS keys:

A filter element consists of a support tube, around which the pleated filter media is wrapped, and two end caps. The pleated filter media with various filter and support materials are the core of the filter element. Depending on the requirements and the hydraulic filter design, different filter materials, filter ratings and types are used for surface and depth filters.

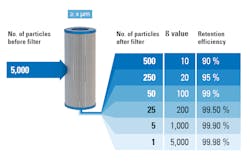

Filter materials use glass fiber fleece (VG, API, WVG), polyester (V) and cellulose (P) nonwovens and papers, and stainless steel wire mesh (G). These materials are available in various filter micron ratings, the retention efficiency of which is designated by the beta value (ß): The larger the beta value, the more particles are retained by the filter and the higher the retention efficiency. The beta value is determined according to ISO 16889 and ranges from ß200 ≥ 4 µm(c) to 25 µm(c) for fiberglass media, which act as depth filters, and from 10 µm to 250 µm for wire mesh media, which act as surface filters.

To ensure reliable, trouble-free operation, all components such as O-rings and filter element load-bearing parts should be selected and, if necessary, adapted according to these specifications. Eaton can also customize filter elements from the existing range special applications. For example, gaskets and adhesives can be customized to withstand extremely low temperatures of up to −58° F (−50° C).

The selection of the right filter element therefore depends on various criteria which, in addition to the requirements for chemical or physical resistance, also include the type of application, the dirt-holding capacity and the associated service life, compliance with the maximum differential pressure and the required cleanliness level of the fluid.

Achieving the Perfect Solution with Expertise

No one knows the operating conditions of a hydraulic system better than its user. Operators can quickly find filter elements that are suitable for their application using their system's key data and Eaton's specifications as reference.

Industries are diverse and every hydraulic application is different. The best way to select the correct filter element is to know the following application parameters—and preferably the technical data of the hydraulic oil too:- What kind of system is being operated?

- Which fluid is being used?

- What is the temperature when the system is in operation and at a standstill?

- How viscous is the hydraulic fluid?

- What is the volume flow rate?

- What is the operating pressure?

- Which purity class is to be achieved?

- What impurities can occur?

Successful filtration in hydraulic applications requires industry-specific expertise due to the large number of possible filter elements and additional components. To ensure that the selected filter elements suit the intended application, system designers should ensure that manufacturers not only offer a broad portfolio of products, but also detailed advice.

Experienced partners like Eaton offer customers comprehensive support based on in-depth industry expertise. Whether mining, stationary hydraulics, mobile applications or wind power—expertise and cooperation as partners make hydraulic filtration more than a mere necessity: It ensures maximum efficiency and safety in operating hydraulic systems and thus becomes a fundamental element of the entire value chain.

This article was written and contributed by Simone Ortner, engineering manager, and Dr. Anastasia Peters, development engineer, at Eaton Technologies GmbH, Altlußheim, Germany.

About the Author

Simone Ortner

Engineering Manager, Eaton Technologies GmbH

Dr. Anastasia Peters

Development Engineer, Eaton Technologies GmbH

Leaders relevant to this article: