Manifolds

Manifolds come in two basic types. One is a single-piece design which supports all necessary valving and contains all the passages for an entire system. The other is the modular-block design. Each modular block usually supports only one valve and contains internal passages for that valves functions as well as flow-through provisions. It normally is connected to a series of similar modular blocks to make up a complete system.

Both types have their advantages. Which is best suited for your system will depend on a variety of actors, such as application, specific function, cost, space, and system longevity.

Some manifold manufacturers supply only manifolds; others provide manifolds that go only with their valves; still others supply manifolds and valves, but are willing to sell you their manifold and permit you to select valves of your choice. As more valves are built with standard mounting patterns, interchangeability becomes feasible for more and more systems.

Single-piece manifolds

These are available in two basic designs: laminar and drilled metal block.

Laminar design " In a laminar-type manifold, several layers of metal have appropriate passages machined or milled through them. These plates, usually steel, are stacked or sandwiched with the various fluid paths determined by the shape of the overlapping passages. Solid-metal end pieces are added, and the whole stack is brazed together.

Because the internal passages can be cut in contoured shapes and as large as necessary, nearly any flow rate can be accommodated with virtually no pressure drop. Because the stack is brazed together, these manifolds can handle pressures to 10,000 psi, and there is no limit to the number or size of the valves which can be mounted on the manifold.

Laminar manifolds are custom-designed. Valves and other connections can be located where appropriate for a specific application. But because of the permanently shaped flow passages and brazed construction, this type manifold cannot be modified easily if future circuit changes become necessary.

Drilled metal-block design " Drilled metal block manifolds, Figure 1, also can be custom-designed for specific applications. Usually made from a slab of steel, aluminum, or cast iron, the blocks are drilled to provide flow passages for design requirements. This network of drilled passages also enables you to locate valves as desired, with some limitations because the drilled passages must be straight.

Other drilled-block manifolds accept cartridge valves into cavities drilled into the manifold surface. Interconnecting flow passages travel through the manifold from the valve cavities. Some cartridge valves have threaded bodies that hold them in threaded cavities; others slip into smooth cavities where they are retained by plates on the manifold surface.

Modular manifolds

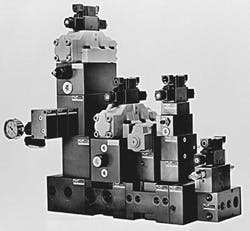

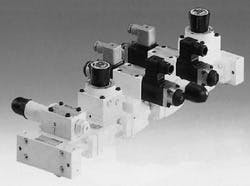

Modular manifold systems, Figures 2 and 3, allow relatively easy modification of existing manifolds. This erector-set approach to manifold construction consists of cast iron, aluminum, or steel blocks which permit you to design and build your own manifold. They also can be ordered ready-to-install. Most modular systems can be bench-assembled horizontally and stacked.

End plates usually seal the ends of the assembled manifold, but these plates also can be drilled for pump and tank connections. Interconnecting, divider, and spacer plates are usually installed between the basic building blocks. Interconnecting plates divert flow from one passage to another between blocks, or stop flow between blocks by plugging a passage. Divider plates allow flow to continue or to be blocked by plugging. Spacer plates serve to increase dimensions between basic blocks when an outsized valve must be accommodated on the mounting surface.

The tops of the basic modular blocks are ported and drilled to accept subplate-mounted valves. Blocks with different ports usually are available for each type of valve and subplate. Each type is identified for the valve it will accept. One company has color-coded their blocks so that block function can be determined visually. Some modular systems will accept cartridge valves as well as subplate-mounted valves. When specifying a manifold system, be sure to examine the interchangeability of valves, subplates, and blocks.

Manifold assembly

The methods of manifold-block connection vary. Some modular manifolds use tie rods which extend through the blocks and are secured with nuts. Some have external flanges on each block which bolt together for connection. Others have a connecting hardware system which uses socket-headed studs which are also threaded in the socket to accept the threads of the next stud.

All blocks and plates have provisions in their fluid-conducting passages for O-rings to provide a seal between sections when they are drawn together.

Some manifold systems have pump and tank connections in the bottom of the block, others locate them in the end plates. One advantage of the bottom port is that pressure fluid can be introduced in the center of the circuit, or at the division between two parallel circuits, thereby reducing the distance through which pressure fluid must flow. An advantage of the end-plate connection is that they permit base-mounting of the manifold, which is convenient on some equipment. Some manifold designs arrange to close-couple the pump to the manifold, eliminating the pressure line to the manifold.

Pneumatic manifolds, Figure 4, often have separate exhausts at each block or work station because there is no need to return this fluid to tank. This permits exhaust metering which in turn, allows individual workstation speed control.

Restrictions

Flow-rates, pressures, and manifold length may be limiting factors with some modular manifold systems. One system is limited to 20 gpm at 3,000 psi, and the manifold package cannot be more than 3 ft long. Another is restricted to 35 gpm and 3000 psi. A third accommodates fluids at pressures to 6,000 psi and has no length limit. These restrictions can be designed around, but be sure the system you specify can adequately handle your needs.

Electrical connections to manifolds may be made with wires which lead directly from the power source to the appropriate solenoid. Some manifold systems have built-in electrical troughs or channels for interior runs of electric cable. Some pneumatic systems have electrical connections at the valve subplate, which provide plug-in connections for the valve. This reduces the maze and clutter of the installation.

Advantages of manifolds

There are many advantages in using a manifold system. An example: a manifold which replaces approximately 300 lb of tubing and valve bases, occupies only about 1 ft3 of space. Design engineers list these advantages and tips for the the use of manifolds.

- assembly and installation costs reduced 30% to 50%

- space required for installation reduced by 33%

- single-pressure-type pneumatic manifolds require only one filter-regulator-lubricator

- placement of all valves and manifolds should be considered during the design stage; manifolds should be located as close as possible to the equipment they are to control

- if four of five valves are to be operated simultaneously, connect the supply to both ends of the manifold

- when designing and specifying a manifold, the system designer should work with the manifold manufacturer. It is nearly impossible to catalog all manifold options or substitute catalog information for the detailed knowledge and experience of the manufacturer.