Cartridge valves add flexibility to excavators

This file type includes high resolution graphics and schematics when applicable.

Engcon AB, Strömsund, Sweden, is the world’s leading manufacturer of tilt rotators — attachments that are installed between an excavator’s boom and bucket to continuous 360° rotation and ±40° lateral pivoting of the bucket or other end tool. Engcon’s tilt rotators are equipped with a hydraulic motor for rotation and double-acting cylinders for optimized tilting force and even load distribution. Engcon´s tilt rotators can be used on most existing excavators and backhoe loaders within a weight range of 11⁄2 to 32 tons. Essentially, they give a machine’s end tool an even wider range of movement than that of the human wrist.

Fine control of movement is provided by a valve block mounted in the lower section of the tilt rotator — a location that helps reduce the risk of it being damaged. Control blocks with screw-in cartridge valves and directional control valves are supplied by Argo-Hytos, Kraichtal-Menzingen, Germany. Argo-Hytos designed its PRM8 balanced proportional valve specifically for this application.

Unlike conventional valves, the PRM8’s servo control is integrated into the valve itself. Electrical and hydraulic interfaces and dimensions of the PRM8 are identical to those of a standard size 06 direct-acting proportional valve, yet it can regulate flows to 85 lpm.

The PRM8-06 valve has a maximum working pressure rating of 350 bar (5080 psi) and maximum flow rating of 140 lpm (37 gpm).

Argo-Hytos designed the valve with internal compensation of flow forces to prevent decreasing the valve’s cross-sectional flow area from an increasing pressure difference (∆P) over the control edge. This ensures a direct proportionality between the flow and ∆P with a constant electrical signal.

Design and simulation

During development, the valve was simulated as a system using MatLab-Simulink. The goal was to optimize the design characteristics prior to creating an initial prototype.

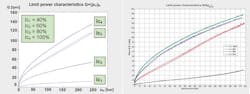

To make the simulation as realistic as possible, data were accessed from existing measurements (such as force-displacement characteristic of the drive system) and from other detail simulation tools such as flow simulations for determining flow forces. The quality of the simulation can be seen in the graphs. They illustrate the result of the simulation and the measuring result of a first sample in direct comparison.

Development times were reduced substantially by using simulation tools in product development. This made reliable data available early in development. The quick and precise implementation of its requirements was also the deciding factor for Engcon when selecting Argo-Hytos for the controlling its tilt rotators.

For more information, contact Argo-Hytos in the US at 419.353.6070 or visit www.argo-hytos.com.

This file type includes high resolution graphics and schematics when applicable.