Multi-Axis Motion Control Streamlines Sawmill Operation

Today’s sawmills are hotbeds of motion control. Modern integrated saw lines rely on coordinating the motion of dozens of moving parts to maximize productivity. For example, AMS Solutions, of Enderby, B.C., Canada, designs customized automation solutions for sawmills across North America. Experts at AMS recently completed the design and installation of a new canter profiler gang saw (Fig. 1), in a dimensional-lumber mill in the Northwestern U.S. The system AMS installed incorporates 26 hydraulic motion axes being managed by a Delta Computer Systems RMC200 motion controller.

On Sawing Wood

Learning what a canter profiler gang saw does helps in understanding the role of motion control in the new mill hardware. When an uncut, debarked log enters a lumber production line, it is fed into a head saw (also called a head rig), which breaks the log into cants (unfinished logs having at least one flat side) and flitches (unfinished planks that are flat on one or two sides with rounded edges). The trimmer drops these boards out to be sent back and re-run through the edger, or a resaw, which has been set up to accommodate smaller board dimensions.

Sending boards back through the edger repeatedly is inefficient. On a busy milling line, this process can create a workflow bottleneck and cost 10 to 15 min. out of every hour of productivity.

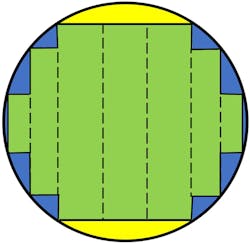

The solution (Fig. 2) is to use a profiler to mill the sides of the cant to their optimal dimensions before feeding the wood through the gang saw. This single operation thereby eliminates the rework step using the edger. Running a profiler requires more motion axes on the gang line, but it can increase log usage and reduce edger load. And as a result, the benefits of a new canter profiler gang promised to incrementally improve the mill’s productivity and output.

Canter-profilers aren’t simple machines. The system designed and installed by AMS was a double profiler, which could profile two boards off each side of a cant simultaneously, enabling the gang saw to cut the different-sized boards from the cant in a single pass. Managing the canter-profiler heads, however, requires controlling a total of 26 motion axes: 11 axes to move the profiling cutting tools on each of the left and right sides, plus four axes for the gang saw (two to control guide rolls that align the cant into the saw and two more to slew/skew the saws to follow the curve of the cant). The motion-control solution for this application needed to be able to control and synchronize the motion of such a large number of axes to get optimal results from the sawmill’s profiler investment.

2. End-on view showing how a log is profiled. First, the head rig chips away the yellow material to make a flat-sided cant, then the profiler chips away the blue material. Finally, the gang saw cuts along the dashed lines to separate all the boards (shown in green) in a single pass.

Selecting a Motion Controller

According to AMS Vice President Richard Vetter, his company selected the RMC200 motion controller from Delta Computer Systems Inc. (Fig. 3) based on the strength of previous Delta solutions. “Delta Computer Systems controllers are standard motion controllers used in the forest products industry,” said Vetter. “We’ve used standard PLCs in the past to do motion control when a large number of axes are involved, but we’ve found that Delta controllers can do more precise tuning of the motion, which…leads to better accuracy and productivity and, ultimately, better profitability for the line.”

All the motion axes are programmed to follow curved paths as synchronized slaves to a master reference axis, the position and velocity of which are monitored using inputs from a rotary encoder connected to the line conveyor. Synchronizing the saw line using the RMC200’s built-in functionality lets the machine vary the speed of the line while automatically keeping the sequencing of process steps intact.

During line operation, a Microtec optical scanner and optimizing computer scans each cant and calculates each motion curve, which is relayed by a PLC to the RMC200. Vetter noted that Delta controllers have a long history of making the programming for such complexity simple enough for a broad base of users—even those without coding expertise.

3. View inside the electrical panel supplied by AMS Solutions for the mill’s Profiling Gang System. The Delta RMC200 motion controller (inset) can control and synchronize the operation of up to 32 motion axes simultaneously.

Programming the Motion

To program the motion, Delta’s RMCTools—a comprehensive set of software programs—simplifies much of the process by using drop-down menus and fill-in boxes to select the functionality and limit values for each axis. Then, with every hydraulic axis installation, a scaling and tuning process inevitably follows the motion programming. To simplify this stage of the development process, RMCTools includes a Tuning Wizard module.

After running the Tuning Wizard—which builds a mathematical model of the system being controlled and proposes control loop parameter gains to optimize the model—users can further adjust the gains, if needed, to precisely dial in axis performance. Beyond this, RMCTools offers a host of functionality to help with anything from motion parameter plotting to setting custom event triggers within the tools’ Windows-based Integrated Development Environment.

“Because it can control up to 32 axes, the RMC200 allowed us to build this application with a single controller module,” explained Vetter. “We could have used multiple Delta RMC150 eight-axis controllers, but synchronizing them would have been more difficult. Now, with the RMC200, we have just one device, one RMC program, and one common place to access and tune the machine.

“We pushed the RMC200 close to its limits in both the number of axes being controlled and use of the system’s communication bandwidth,” he cntinued, “but the motion controller performed beautifully in fulfilling the profiler’s needs.”

Better Motion Control Makes the Difference

With the new installation just entering production, the mill’s controls engineer is looking forward to pushing the RMC200 even harder, working into increasing line speeds and handling bigger logs. The engineer wants to start relatively gently, but he knows he can tune the RMC200 into flawless running at full production. There may be small quirks that need solving, but he’s worked with Delta Computer Systems support staff and prior RMC models before and knows that any issue will be quickly resolved.

Without a profiler, and relying just on traditional edging, it would have taken some boards five or six passes to reach the trim line and get stacked out into lumber. With the new profiler and the RMC200, the mill is already seeing an improvement of about 5% in the productivity of the line, with more to come. And that represents a real dollar value increase in output per year.

Brad Smith is a regional technical sales manager at Delta Computer Systems Inc., Battle Ground, Wash. For more information, visit www.deltamotion.com.

About the Author

Brad Smith

Regional Technical Sales Manager

Leaders relevant to this article: