Guidelines to Avoid Those Hydraulic-Cylinder Headaches (.PDF Download)

The term “high pressure” is quite subjective when it comes to hydraulics. Among the strictest definitions is any system with operating pressure exceeding 10,000 psi. Perhaps a more general interpretation is 6,000 psi, which will be assumed for this discussion. In this article, high system pressure will be defined as 6,000 psi (410 bar), which is the pressure setting on some newer excavator functions.

A system that operates at 6,000 psi will see brief pressure spikes that are two to three times the 6,000-psi working pressure. This means the components need to accommodate 12,000 to 18,000 psi (827 to 1,241 bar) pressure spikes for a reasonable service life of 8,000 hours (about four years), and should not fail in less than 2000 hours—about one year of service.

Because most of my extensive learning experiences are from working with logging and construction equipment attachments, the examples I have set forth are from those industries. I chose not to blame the customer for using the cylinders differently than I specified, and I accepted full warranty responsibility for any poor design choices. Several cylinders were repaired under warranty several times, and a few cylinders were scrapped and completely new designs were implemented to meet the self-imposed one-year or 2,000-hr warranty.

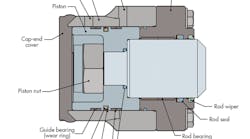

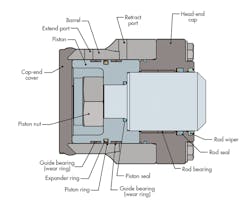

The concepts and areas of focus being presented here can be applied to most hydraulic cylinder applications. Components of a typical cylinder are illustrated in Figure 1.

1. This sectional drawing shows the main components of a high-pressure hydraulic cylinder.

Cylinder Design Considerations

What is actually being done with the cylinder and how is the cylinder being loaded? When designing a machine or attachment, the designer has an idea of what the unit should do and how it should be done. As soon as you hand the machine over to a different operator, the application, duty cycle, and operating parameters have changed. In some cases, the change is enough that things start to fail. Frequently, a cylinder will be subjected to a work-induced load that is much greater than what is possible via direct control.